Supply Shortages Causing Problems At BHS

Photo by Sloane Contrino

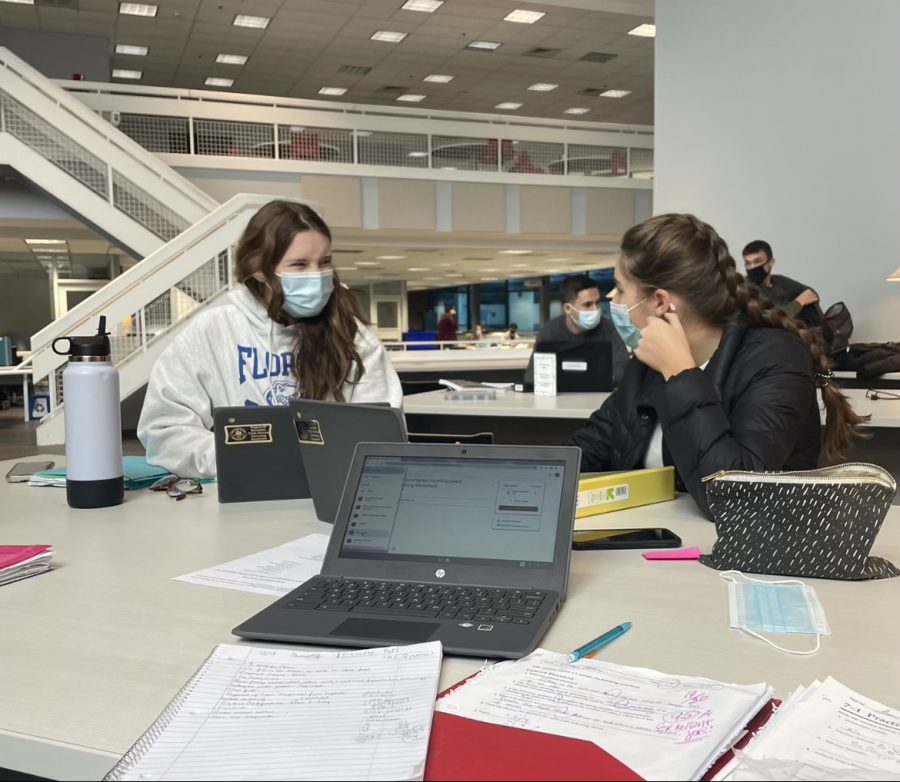

Sophomores Laina Nickerson and Elise Abreu using their computers to access their worksheets due to no toner in printers.

December 9, 2021

The date of March 13, 2020 is commemorated with rehashed images — wild frenzied shoppers desperate for a shred of toilet paper. This marks when scarcities brought on by the global pandemic began. Twenty months later, the effects of Covid-19 on supply chains are still present at Barnstable High School. Teachers can’t find toner in order to print paper copies. Students lose RFID cards faster than microchips can be made. Brooke Styche, English teacher, pushes the door to BHS open, hands full of copies made at Staples, paid for with her own money.

“We adapt,” said English Teacher Meghan Fligg, when asked by a student in class what they do when paper cannot be printed. The community turns to other resources when there’s no paper copies to be made. Google classroom, Nearpod, Quizlet and other online platforms previously used with remote learning have been re infused into teacher’s teaching and students’ learning with a toner shortage.

Monice Maurice, business and entrepreneurship teacher, has seen change in her job since the change. She reviews and teaches vocabulary by playing bingo on paper game boards. Her classes have adapted to doing this on an active google doc, which allows students to edit and cheat as they go, defeating some purpose of the activity. With opportunities to make work easier by doing this, students still want, and prefer, paper copies.

“Have you not seen the shortage everywhere?” Maurice said to a student when they asked for paper.

Without printing resources, there are less options to teach different learning styles. In addition to online activities, Maurice also had to scan pages of a book for an upcoming class project, rather than handing students their own paper copies. This was not her original plan.

Returning from Thanksgiving break, the DECA mock competition took place. Students are presented with a scenario on paper; the process of the event then follows. Not enough copies could be made. Students resorted to taking photos of the paper materials and referring to that. “Even though we were back in person for DECA this year, that part still felt like we were online,” said club member, Sofia Atsalis.

The pandemic created unprecedented patterns in everything, including business. Supply in many chains stands still, unprepared for unexpected change. If not steadfast, supply for other items lags heavily, due to COVID-19. Although microchip and toner shortages trace back to manufacturing in Asia, the the United States is facing struggles in allocation of goods. Sharon Morgan, librarian at BHS, has not been effected by the toner shortage, but she sees how it is affecting her colleagues, specifically those who previously printed from the library on frequent. Morgan is not certain of details behind shortages, but what she and other staff members do know, is that the United States is working on it.

New supply chain moves by the Biden administration this month are aimed at combating slow delivery of goods and the rising prices of fuels, according to an article by The Washington Post. Organization of which containers arrive at which ports has been a main focus. The article also touches on freedoms of privately owned enterprises, notably those responsible for the pipeline of products in distribution channels. Liberties of ports, terminals, and other institutions that issue the allocation of goods go beyond these federal guidelines. Accordingly, Maurice said the situation is complicated, and consumers in the United States will continue to compete for scarce resources.

Affecting the BHS community outside of their school lives, students report troubles finding “juice pouches” in stores, along with certain Gatorade and sports products like wax and tape. Some have turned to canned beverages rather than Caprisun, or going “commando” in field hockey, meaning without a stick grip. Most pressing of all, students have struggled to find adequate used cars.

“I can’t afford anything that’s available. Because new cars are scarce, used cars are now in higher demand than ever,” said junior Gianna Scibelli, who has done her fair share of car research. “It’s been six months and there still hasn’t been anything I can find.”

Inside BHS, staff and students adapt to supply chain shortages that affect their teaching and learning as well as general productivity. “There’s been a sort of static in the air, reminiscent of all the pauses last year, when options were eliminated, and the pandemic left us with few solutions to problems and little action,” said sophomore Sophie Anderson.

Outside the building, consumer culture flourishes as members of the community find alternative products to what they’re looking for.